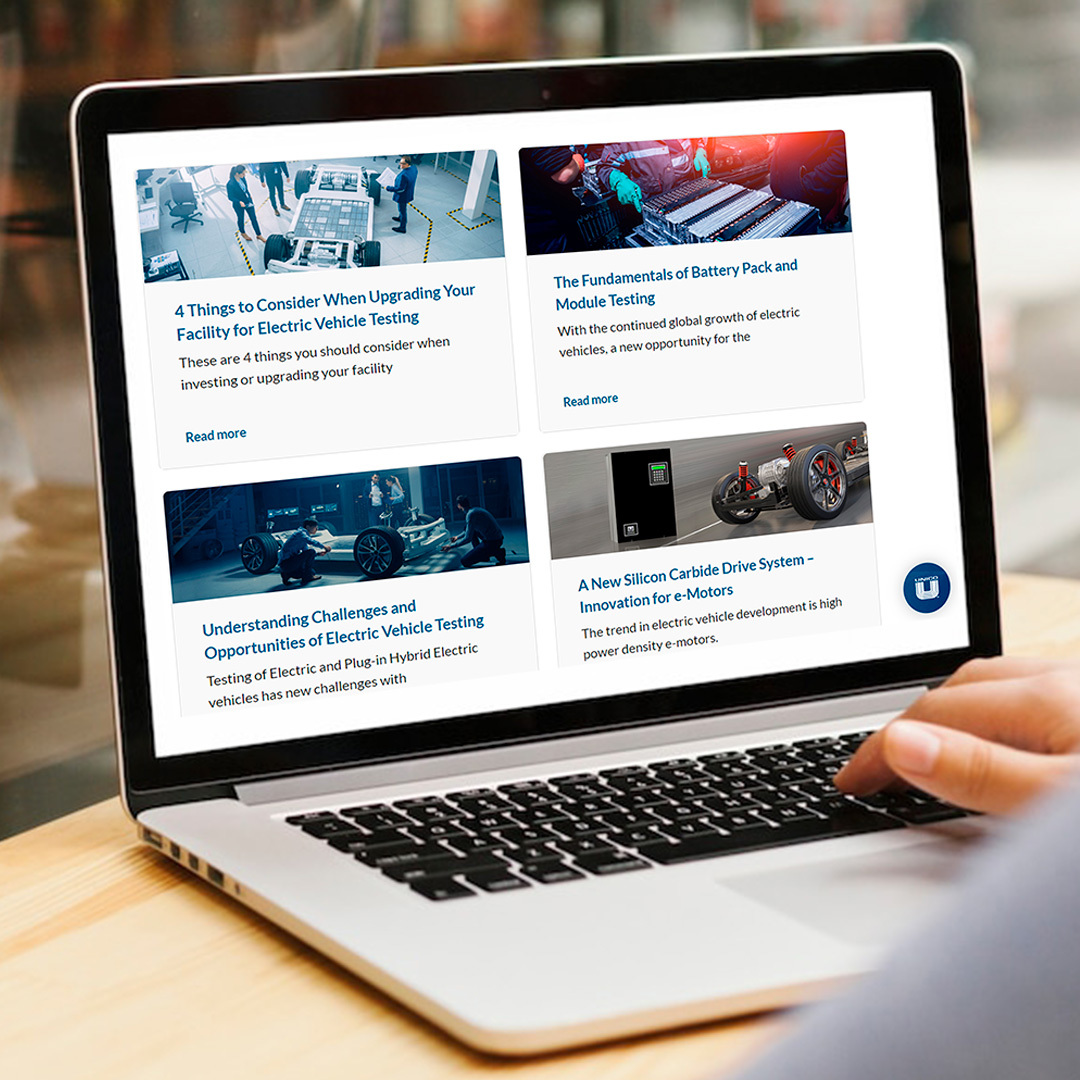

These are 4 things you should consider when investing or upgrading your facility for electric vehicle testing and e-powertrain testing to get the most out of your investment

- Upgrading an engine testbed to an e-drive or e-motor testbed

- Benefits of Common Bus Systems for e-Powertrain Development and Testing

- Open Communication Protocols

- Advanced Hardware in the Loop Applications

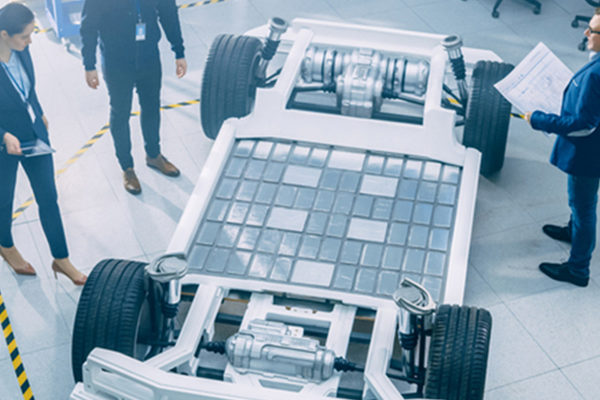

To obtain the promised efficiency benefits of hybrid and electric vehicles, it is important to conduct driveline and component testing during design and manufacturing, specially adapted to the actual nature of hybrid and electric vehicles. Such drivetrains have several features that make testing them very different from the quality testing conducted on legacy fueled systems. For instance, hybrid and electric systems use regenerative braking, which usually requires complex AC inverter technology, and sometimes more complex transmissions.

Changing technology and increased complexity in mobility requires a testing system very different, and more complex, than those utilized in Internal Combustion Engine vehicle.

Upgrading an engine testbed to an e-drive or e-motor testbed

Unico is often asked by our customers about upgrading one of their originally delivered engine testbeds to support e-motor or e-drive testing and development. While the basic question of the new speed and torque requirements of the dynamometer needs to be addressed, there are a few additional things to consider when planning this type of project.

Low Speed Control

In a traditional internal combustion engine (ICE) testbed, the engine’s lowest operating speed is at its idle speed, or somewhere in the 500rpm range. The engine’s output is then goes through a transmission with a clutch for when the vehicle is starting from a stop. So, the dynamometer operating range is from this idle speed up to the engine redline.

However, much of the e-motor operates near 0 RPM when the vehicle is just starting to move. This is also a point where the driver experience is heightened – as this happens often. The driver doesn’t benefit from the inertia of the vehicle for smoothness, and poor control strategies are very apparent in low-speed maneuvers. To provide very good control strategies of the Electric Vehicle during these operating conditions, the e-drive testbed must be able to operate at these very low speeds, very often less than 1 rpm. This would rule out the use of passive dynamometers such as Eddy current or water brakes as neither types can be controlled from 0 rpm.

Full Control in Forward and Reverse

In addition to very precise low speed control, the testbed needs to operate in reverse direction. Unlike a typical ICE drivetrain with a reverse gear where the engine is always running in the same direction, an e-drive has the benefit of simply running in reverse. This is great for efficiency, but you must make sure that the test automation system of the testbed and the dyno can also be run “in reverse”.

Universal Inverter

The E-Drive consists of both the e-motor and the traction inverter providing the energy to the e-motor. However, the ability to test the e-motor without the production traction inverter also has benefits. For example, if there are issues with the traction inverter, the e-motor can still be tested. To do this, you would need a universal inverter to replace the traction inverter and having this capability from the beginning could prevent headaches from adding it later.

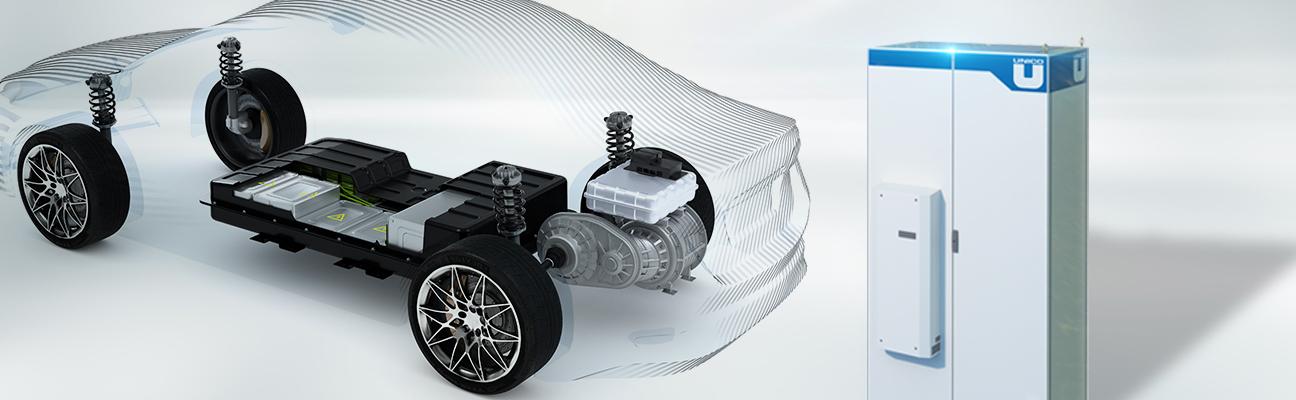

Battery Emulator

Finally, the E-Drive needs to have a DC voltage from an energy source to emulate the vehicle battery. This is either a static constant setpoint voltage source which provides the E-Drive with the required power to operate, or you may incorporate a battery model and then react to the current demand based on the SoC and temperature in the model. Either way, a good energy source is needed and if this energy source can share the mains connection and have a common DC bus connection to the dyno drives, efficiencies, cost reductions, and floor space requirements can be achieved.

Benefits of Common Bus Systems for e-Powertrain Development and Testing

In the world of E-Mobility, technology changes fast. Battery voltages, motor types, motor speeds and more are all a moving target. If you are developing products for this market, you need a testing solution that can keep pace. Unico’s common bus drive systems are the answer.

Consider the case of E-Motor testing. Unico is able to offer a modular solution that combines an AC Dyno, Battery Emulator, and Universal Inverter, all in a single package and powered by a single active front end. This combination package saves floor space, reduces wiring complexity, simplifies installation, and saves energy.

Open Communication Protocols

Testing hybrid and electric vehicles are very different from the testing of the traditional internal combustion engine, which usually measures speed, torque, temperatures, pressures, and flows. In electric vehicle testing you are dealing with so many different communication protocols, it is essential to have open communication protocols.

Modern hybrid/EV test systems must provide all the functionality of traditional systems, with the added ability to check high-power regenerative electrical drives, high voltage battery and charging systems, and communicating with any number of smart control modules (MCU’s and ECU’s).

In today’s world, several larger hybrid/electric vehicles have a trend toward using higher-voltage, higher-efficiency drive systems. To conduct this sort of testing, it is essential to use a 4-quadrant dynamometer, which can test all modes of operation (motoring and regenerating) in a hybrid or electric powertrain or vehicle.

Unico systems feature an open communications protocol to accept commands from existing customer controllers that are used to generate test profiles. Wired and fiber-optic options are available. Supported protocols include:

- CANbus

- LonWorks

- ControlNet Modbus Plus

- DeviceNet

- Modbus TCP

- EtherCat

- Profibus

- Ethernet I/P

- ProfiNet

- Interbus S

- USB

- Other protocols available on request

Advanced Hardware in the Loop Application

XIL, HIL, and SIL are essential components of the development of the E-Mobility powertrain. Unico drives are well suited to interact with various real time simulation platforms and offer synchronous communications to execute customer models.

The way forward

Test stands play a vital role to help automotive, heavy equipment, military, and aerospace industries move towards improved performance of hybrid and electric vehicles along with energy efficiency and green footprint.

With an unparalleled level of engineering expertise and a long history of working with the top names in the Motorsport, Automotive, and Aerospace sectors, UNICO is the logical choice when performance, reliability, and accuracy are paramount.