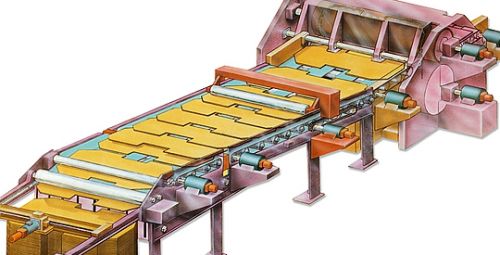

The RDC drive controls a rotary die cutter for corrugated, paper, and other nonmetallic web applications.

Specifically engineered die cutter application software embedded within the drive eliminates the need for an external controller. When used in conjunction with a programmable logic controller (PLC), the drive forms a powerful automation work cell that can be easily integrated with other Unico automation cells to build a complete processing line control system. The drive can also be configured to stand alone with discrete I/O and a dedicated HMI.

Embedded control reduces system complexity while taking full advantage of the exceptional performance, flexibility, and ease of use of Unico drives.

Printing Modes

The rotary printer control prints on a continuous web or on precut fed sheets. Three different modes offer the choice of printing relative to a leading-edge sheet sensor, relative to registration marks using a mark detector to scan the web, or at a settable repeat interval. Windowing features minimize spurious mark errors during registration printing.

Constant-Velocity or Cyclic Modes

Master/slave control simulates line shafting and can replace traditional mechanical gearing in constant-velocity applications. A cyclic mode allows single or multiple printing plates per revolution of the cylinder, giving the flexibility to run repeat registers longer than the register repeat length of the machine.

Dynamic Register Correction

A dynamic correction feature ensures repeated registration on the fly, eliminating the traditional trial and error as well as the associated scrap. In constant-velocity mode, this feature may or may not be used depending upon the web and printing dies on the cylinder. Small corrections are possible within the revolution when the printing dies are not in contact with the web or where there is minimal contact without web or die damage. In cyclic mode, correction is automatic and occurs during disengaged angle(s) of the printing plates on the cylinder. The maximum correction per cylinder revolution is a scalable variable.

Simulators

Simulation tools facilitate setting up, testing, and troubleshooting a rotary printer system. A line simulator makes it possible to run the printer without material by simulating material feedback. A mark detector simulator provides marks at a specified separation to allow testing in print-to-mark or repeat print modes.

Micro Advance/Retard Adjustment

A micro adjust feature compensates for errors caused by slippage or register mark variation.

Maximum Line Velocity Calculation

The program calculates the maximum velocity at which the line can operate in cyclic mode. The velocity is computed using a number of parameters that describe the angles of engagement and number of stops per revolution of the print cylinder.

Cam Outputs

Software-generated programmable limit switch (PLS) outputs replace mechanical cams by electronically following the position of the print cylinder. These cams can be used to trigger/cycle external devices with each cylinder revolution.

Smart AC Digital Drives

Unico’s 1000 and 2000 drive families provide powerful, flexible digital flux vector control for sophisticated, performance-oriented applications. The drives have been designed for complete flexibility and offer a variety of feedback, programmable I/O, and communication options. They incorporate a number of energy-conserving features, including line regenerative capabilities for exporting energy back to the power grid. Both drive families can take advantage of a modular DC bus configuration for sharing or recirculating energy among multiple drives.

Communication Protocols

The drive supports a variety of serial communication protocols for connecting to virtually any PLC or HMI. The drive can also operate in a stand-alone mode using the built-in keypad/display or using an ANSI or RTU protocol connection to a simple serial display unit.

|

|

|

|

†Supported only by the 2000 family platform |

||

Inputs/Outputs

All inputs and outputs are user-enabled and are mapped to hardware I/O points to allow customization of the control. They are also accessible through a high-speed serial communication link.

| Inputs | Outputs | |

|

|

|

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Contact Unico Support

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Talk to our Sales Team

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |