TST800 SERIES OVERVIEW

Revolutionize your electric and hybrid vehicle development with UNICO’s Active AC Load, the ultimate solution for traction inverter testing in electric and hybrid vehicles. While a full eMotor emulator may dynamically simulate an inductance or the ripple current associated with the inverter’s PWM ripple frequency, this is often not necessary for many inverter test applications. An Active AC Load is specifically designed to allow full power testing, which is not possible with passive loads, while adding the ability to emulate an RL load or motor back emf as seen by the inverter at any power factor. This makes UNICO’s Active AC Load a more cost effective and powerful solution suitable for most inverter validation applications. The seamless integration with open communication protocols simplifies connection to your current electric vehicle testing setups. Plus, if you’re already using UNICO’s regenerative battery emulator system, our modular design ensures easy expansion.

APPLICATIONS

- Research & Development

- Validation

- Durability

- End of Line Testing

- Test to Global Standards (LV123, ISO26262, and more)

- Communication and integration testing

- eMotor production tolerance checks

FEATURES

- Software Adjustable Power Factor (Motor) removing the need for complex physical (L-R) matrix

- Resistive & Inductive load modeling

- Motor feedback emulation

- V/Hz control mode

- More complete testing than HIL or passive load emulation

- Realistic power factor modeling

- Back EMF modeling

- Inertia torque modeling

- Wide variety of communication protocols available

BENEFITS

OPTIMIZED POWER FACTOR

Maximizes testing efficiency and accuracy with an optimized power factor.

REGENERATIVE POWER

CAPABILITIES

Conserves energy and reduces operational costs with a sustainable, regenerative power model.

BALANCED PERFORMANCE

-TO-PRICE RATIO

Offers high end Active AC Load performance at an accessible price, providing value for a wide variety of inverter testing applications.

ENHANCED SYSTEM

RELIABILITY

Ensures dependable and consistent testing outcomes with a robust design tailored for rigorous, longterm use.

ACTIVE AC LOAD FOR INVERTER TESTING - TST800

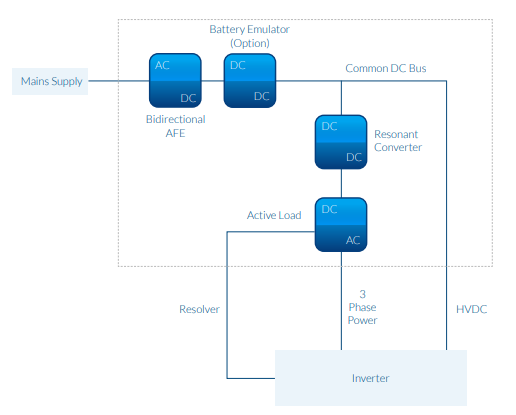

The UNICO Active AC Load epitomizes the fusion of precision and innovation, essential for the development and validation of electric drivetrains. At the core of this system lies the SiC INVERTER, ensuring both performance and efficient functionality. This dedicated test system is designed to deliver reliable and reproducible results, which are crucial for advancing electric vehicle technology. Comprising both an Active AC Load and an optional battery emulator, the UNICO system eliminates the need for

actual eMotors and batteries during the initial testing phase. This not only streamlines the testing process but also reduces setup times and costs, allowing for immediate commencement of comprehensive testing procedures.

Unico’s Active AC Load allows early testing of traction/drive inverters to prevent prototype eMotor failure, offering precision and flexibility with a fundamental frequency up to 1500Hz and the ability to emulate motors from 2 to 64 poles. Fault injection verification is preprogrammed for efficient error tracking, and the system is user-programmable to match various eMotor designs closely. Additionally, it supports numerous communication protocols, ensuring compatibility with most industry-standard automation systems, and includes comprehensive safety and protection features to safeguard both the equipment and personnel.

| Specifications | |

|---|---|

| Power | 30kW to 800kW |

| Motor voltage | Up to 750VRMS |

| Number of poles | 2 to 64 |

| Back EMF | Standard |

| Full four-quadrant | Standard |

| Inertia torque | Standard |

| Fundamental frequency | Up to 1500Hz |

| Encoder type | SinCos, Resolver |

| Resolver | • Poles: 2 to 64 • Offset: -2 π to 2 π radians • Excitation: 2kHz to 20kHz |

| Programmable parameters | • Direct inductance Ld • Quadrative inductance Lq • Magnetic flux • Winding resistance |

| Fault simulation | • 3 Phase open circuit • Phase to phase short circuit • Motor stalling • Demagnetization • Sensor phase shift |

| Internal data logging | Up to 32kHz |

| Model calculation | Up to 32kHz |

| AC Input | 400-480VAC, 3Ph, 50/60Hz (other voltages available on request) |

| Ambient | Up to 40°C, max 1000m above sea level, 95%RH non-condensing |

| Enclosure | NEMA 1 (other options available upon request) |

| Cooling | Air cooled, Open loop liquid cooled, closed loop liquid cooling |

| Cabinet Paint | RAL 7035 Rough Semi-gloss Poly Powder finish |

| Certification Compliance | UL (other certification available) |

| Control | Local and remote |

| Built-in remote interface | Analog as well as RS-422, RS-485, two ports (other interface and protocol, see options below) |

| Safety and control interlocks | Hardwired, opto-isolated, software configurable |

| Battery Emulator Specification | See Battery Emulator Brochure for available voltage, current and power ratings |

| Options | |

|---|---|

| Isolation transformer | Various sizes as required |

| Insulation monitoring | Available |

| Additional analog and Cabinet paint finish | Technical discussion required |

| Cabinet paint finish | Customer specific |

| Protection class | NEMA 12 |

| External communication interface | • CAN open • CC-Link • Ethernet • Profibus DPV1 • EtherCat (sync) • Ethernet IP |

Corporate Headquarters

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

Join Our Team

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Contact Unico Support

Reach us for any enquiry

Disclaimer

Please see our Privacy Policy which outlines the types of information we collect and how we use it, and that we will respect your wish to opt-out of our communications at any time.

Corporate Headquarters

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

Join Our Team

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Talk to our Sales Team

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

Disclaimer

Please see our Privacy Policy which outlines the types of information we collect and how we use it, and that we will respect your wish to opt-out of our communications at any time.

We use cookies on our website to give you the most relevant and seamless experience. To accept all cookies, click “Accept All”, or provide controlled consent by visiting "Cookie Settings".

Manage consent

Privacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.