BAT350 SERIES OVERVIEW

UNICO’s high current cell formation channels are a cost-effective way to achieve the necessary currents for rapid formation in a package that is ready for integration into a cell manufacturing line. The fully regenerative channels provide clean and efficient power

for charging and recover energy during discharging. Pulse formation charging can also be achieved due to the FPGA-controlled SiC power stages with, full current pulses as short as 1ms.

NEXT GEN CELL FORMATION

Performance

Reliablity

Efficiency

Flexibility

Value

Compact

BENEFITS

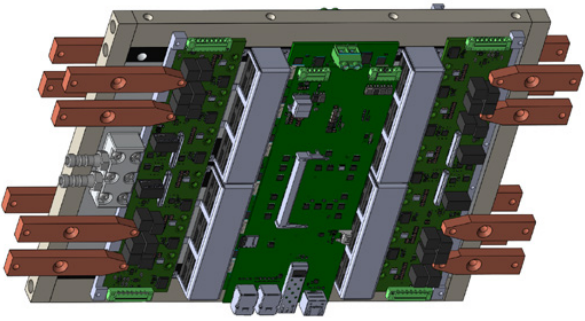

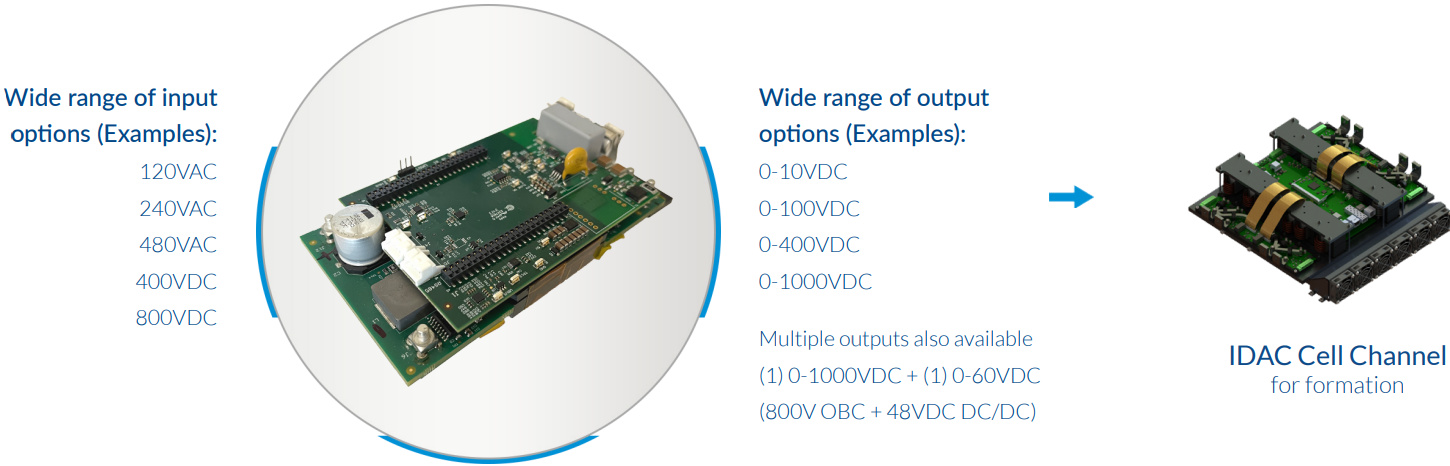

FLEXIBLE OUTPUT AND CONTROL

Flexible, Isolated DC Outputs

• 4-Channel, 0-5VDC at the Cell

• Built-in charge and discharge profile storage

• ±100A or ±300A per channel

FLEXIBLE POWER INPUT

Common AC or DC Bus

• 400-850VDC

• 380-480VAC (future)

EXTREME EFFICIENCY

Significant Energy Savings for Formation

• Better than 95% efficiency

• Fully bi-directional for energy efficient formation

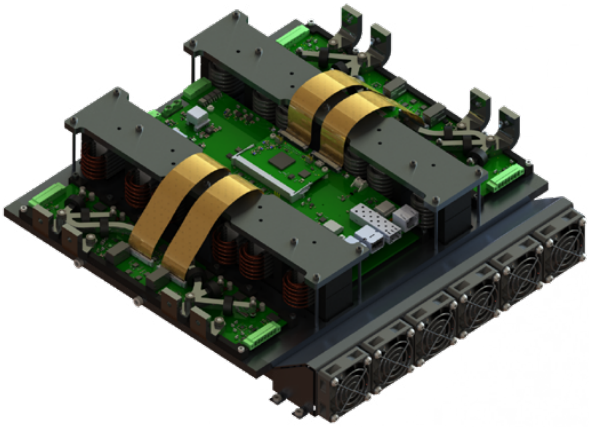

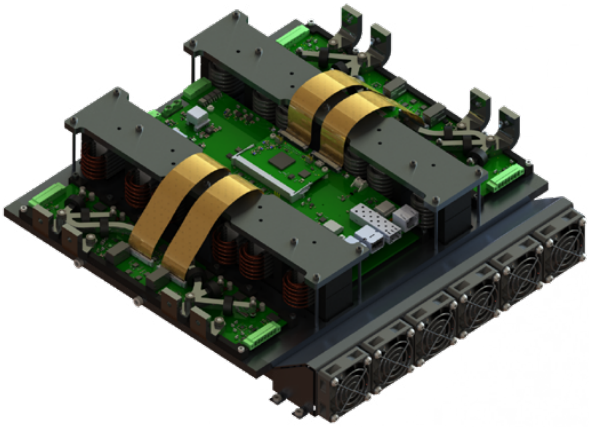

ULTRA COMPACT PERFORMANCE

Flexible Integration into Formation Lines

• Up to 12kW/L power density

• High performance, interleaved SIC power stages for low output ripple

• Air or water cooled with same design

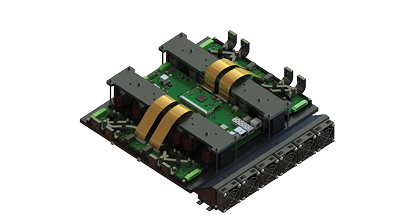

CELL FORMATION WITH IDAC - BAT350 SERIES

FLEXIBLE COOLING METHODS

Air Cooled Example

(1) BAT350

Water Cooled

(2) BAT350’s with a shared Heatsink

BAT350 CORE TECHNOLOGY - UNICO IDAC

ULTRA COMPACT AND EFFICIENT POWER CONVERSION

| Target Specifications | |

|---|---|

| Input Voltage: | 400-850VDC or 380VAC-480VAC +/-10%, 50/60Hz (future) |

| Separate Control Voltage: | 24VDC |

| Output Voltage: | 0-5VDC at the Cell |

| Output Current: | ±100A or ±300A |

| Output Power: | 600W for 100A or 1500W for 300A per Channel |

| # of Output Channels: | 4 |

| Efficiency: | Better than 95% Fully Regenerative |

| Minimum Current Accuracy: | Better than 1% FS (±3A) |

| Target Current Accuracy: | Better than 0.1% FS (±0.3A or ±300mA) |

| Minimum Voltage Accuracy: | Better than 0.1% FS (±0.01V or ±10mV) |

| Target Voltage Accuracy: | Better than 0.01% FS (±0.001V or ±1mV) |

| Control Modes: | CC, CV, CP + Limits & Safeties |

| Cooling: | Air or Water |

| Remote Voltage Sense: | Yes |

| Charge/Discharge Profile Storage: | Yes |

| Pulse Charging/Discharging Capable: | Yes |

| External Contactor Control: | Yes, 1 contactor per channel |

| Internal Temperature Measurement: | Power Circuits & Power Terminals |

| External Temperature Measurment: | Yes, 1 thermistor per channel |

| Control Protocol: | REST API over Ethernet |

| Visual Feedback: | Basic LED Status Feedback |

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Contact Unico Support

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Talk to our Sales Team

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |