E-Axle Dyno Drive

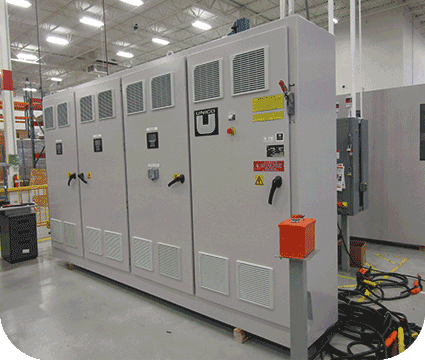

E-Axle Dynamometer Drives to test the EV propulsion system, simulating resistance at the axle of the vehicle. Common DC Bus offers flexibility, cost savings, and configuration not normally possible with traditional drives.

Develop and test your EV propulsion systems with simulated resistance using Unico’s E-Axle Dyno Drive.

This leading edge E-Axle dynamometer is a modular design that allows for multiple types of drive elements to be connected to the common DC bus. Combine mutliple AC dynamometers and E-Motors with a battery emulator and univeral inverter. Power ratings from 50kW to 1000kW, with higher power options available. Support induction and permanent magnet motor dynamometers. Highly efficient and fully regenerative, the system is capable of steady state, transient, and high dynamic simulations. Supports most industry standard communication protocols, making it versitile to work with any automation systems platform. Multiple programmable and preset safety features. Enclosures can be ordered with air cooled or water cooled designs.

E-Drive Dynamometer Drives to perform repeatable performance testing on the E-Drive under test. High efficiency design, high speed, water and air cooled options, and ratings up to 5MW.

Unico’s E-Axle Dynamometer Drives uses a modular design inverter for full regeneration to the three-phase power grid. A proprietary digital current regulator and a state-of-the-art controller allows you to operate any AC dynamometer motor (Asynchronous Induction, Synchronous Permanent Magnet, and IPM – Internal Permanent Magnet) without the current-loop setup required by conventional drives. And IGBTs with a switching frequency up to 30kHz, gives you the performance to run high speed dynamometer motors to match high speed requirements of the E-Motor under test.

Incredible speed and torque response with acceleration rates up to 300,000 rpm per second so you can confidently test with realistic load resistance for aggressive launch control modes, motoring, hill climb, and a variety of throttle applications. Ultra-quiet operation mode using built-in dual current regulators is ideal for NVH testing in both anechoic and hemianechoic test cells.

The drive features full automatic tuning capabilities that can be operated from either a remote terminal or the drive’s built-in keypad. After entering the motor nameplate data, the auto-tuning algorithm automatically identifies the additional parameters for operating the attached motor and configures itself for operation.

Unico’s dynamometer drive provides internal inertia simulation. The inertia simulator can simulate both fixed and dynamic inertias using either internal inertia models or an external real-time command from another controller.

The torque control loop can be closed internal to the drive without requiring any additional hardware to the system. The drive can also close the torque loop on an external torque transducer while using the internal torque estimator feedback at the same time. This provides the accuracy of the torque transducer while gaining the responsiveness of the torque estimator.

The drive has full four-quadrant operation with the ability to limit or block operation in any of the quadrants. This allows operation to be matched to the application. Additionally, the drive can limit the power in both motoring and regenerating modes.

The drive incorporates internal quadrant limiting that can be set for either full or partial blocking, depending upon the application.

Supports most industry standard communication protocol, making it versatile to work with any available automation system platform. A high-speed communications interface is optionally available to accept commands from existing customer controllers that are used to generate test profiles. Wired and fiber-optic options are available. Supported protocols include:

Built-in safety and control interlocks are hardwired, opto-isolated, and software configurable to protect your investment and team. And with cabinet enclosure cooling options of air-cooled, water-cooled, and air-conditioned, this system will keep up with your testing and development program.

| Power | 30kW to 1100kW |

|---|---|

| Motor Voltage | 230 VRMS, 460 VRMS, 520 VRMS, 690 VRMS |

| Full Four Quandrant | Standard |

| Max Dyno Speed | 30,000 RPM |

| Fundamental Frequency | 1500Hz |

| Encoder Type | Resolver, Quadrature, SinCos |

| Internal Data Logging | 250kHz or higher |

| AC Input | 480Vac, 3Ph, 60/60Hz (other voltages available on request) |

| Ambient | Up to 40°C, max 1000m above sea level, 95% RH non-condensing |

| Enclosure | NEMA 1 (other options available upon request) |

| Cooling | Air cooled (water cooled or airconditioned cabinets upon request) |

| Cabinet Paint | RAL 7035 Rough Semi-glass Poly Powder finish |

| Certification Compliance | UL (other certifications available) |

| Control | Local and remote |

| Built in remote interface | Analog as well as RS-422, RS-485, two ports (other interface and protocol, see options below) |

| Safety and control interlocks | Hardwired, opto-isolated, software configurable |

| Isolation transformer | Various sizes as required |

|---|---|

| Insulation monitoring | Available |

| Remote voltage sensing | Available |

| Additional analog and digital input, output | Technical discussion required |

| Cabinet paint finish | Customer specific |

| Protection class | NEMA 12 |

| External communication interface | CANopen, CC-Link, ControlNet, DeviceNet, Ethernet, EtherCAT (async), Interbus, LonWorks, Modbus Plus, Profibus DPV1, Profibus Master, EtherCat (sync) |

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |