Introduction:

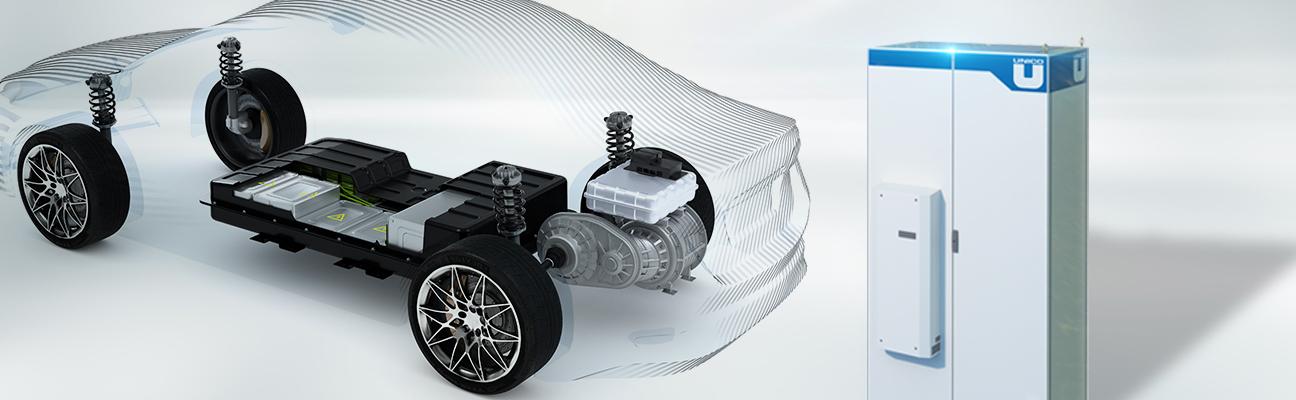

The exponential expansion of the Electric Vehicle (EV) industry has inaugurated a fresh era in the field of transportation. As EV Original Equipment Manufacturers (OEMs) strive to deliver vehicles that are not only innovative and efficient but also safe and reliable, adhering to EV battery standards becomes paramount. In this article, we will delve into the critical factors that EV OEMs must consider when designing vehicle battery systems to meet and exceed EV battery standards, ensuring a seamless integration between technology, safety, and performance.

1. Battery Chemistry Selection:

Selecting the appropriate battery chemistry is the foundation of any successful EV battery system. Different chemistries offer varying trade-offs between energy density, cycle life, thermal stability, and cost. The chosen chemistry should align with the intended vehicle application and overall performance goals while adhering to standards that regulate chemical composition, stability, and toxicity.

2. Thermal Management:

Efficient thermal management is crucial to prolonging battery life and ensuring safe operation. EV battery standards emphasize maintaining battery temperatures within optimal ranges to prevent thermal runaway and degradation. OEMs need to design effective cooling and heating systems that evenly distribute heat and cold throughout the battery pack, preventing hotspots and ensuring consistent performance.

3. Cell-to-Pack Integration:

Integrating individual battery cells into a cohesive battery pack requires meticulous attention to detail. EV battery standards highlight guidelines for cell spacing, mechanical connections, electrical connections, and insulation to prevent short circuits and ensure the longevity of the pack.

4. Safety Protocols and Redundancies:

Safety is a top priority in the design of EV battery systems. Meeting battery standards entails implementing robust safety protocols and redundancies to handle potential failures. OEMs should incorporate features like thermal shutdown, overcharge protection, and state-of-charge balancing to prevent hazardous situations and extend battery life.

5. Communication and Monitoring:

EV battery standards also cover communication and monitoring systems that enable real-time data collection and diagnostics. EV OEMs must design Battery Management Systems (BMS) that can accurately monitor cell voltages, temperatures, and state of charge. Compliance with standards ensures proper functioning of these systems, allowing for early detection of issues and optimized battery performance.

6. Environmental Impact:

Sustainability and environmental considerations play an essential role in modern EV design. Adhering to EV battery standards involves responsibly managing battery end-of-life scenarios, including recycling and disposal processes. Meeting recycling and disposal guidelines helps minimize the environmental impact of EV batteries throughout their lifecycle.

7. Testing and Certification:

Finally, designing EV battery systems in line with standards necessitates rigorous testing and certification procedures. These tests evaluate various aspects, including electrical performance, thermal behaviour, mechanical robustness, and safety features. Meeting or exceeding these standards instills confidence in both manufacturers and consumers and facilitates regulatory approvals.

Conclusion:

As Electric Vehicle OEMs continue to shape the future of transportation, adhering to EV battery standards remains a cornerstone of success. Designing vehicle battery systems that align with these standards ensures safety, performance, and reliability for both manufacturers and consumers. By meticulously addressing factors such as battery chemistry, thermal management, safety protocols, communication systems, and environmental impact, EV OEMs can create vehicles that not only meet the demands of the present but also pave the way for an electrified future that is both innovative and sustainable.