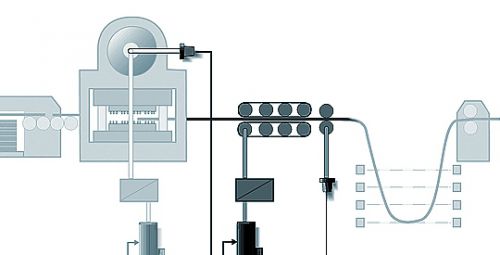

The FTR™ drive is engineered specifically for controlling feed-to-register applications that use a sensor to detect a preprinted mark or mark pattern and index the web with a settable feed length.

Control software embedded within the drive eliminates the need for an external control rack. When used in conjunction with a programmable controller, the drive forms a powerful automation work cell that can either stand-alone or be easily integrated with other Unico automation cells to build a complete control system for a web-processing line.

Embedded control reduces system complexity while taking full advantage of the exceptional performance, flexibility, and ease of use of Unico drives.

Single-Stroking Profile Mode

In this mode, the feeder follows an internally simulated profile using the feed initiate and cut engage inputs to control the feed cycle. The feeder starts the feed when the feed initiate input is set. When the feed is complete, the feed complete output is set. The press can then be cycled to clear feed initiate and set the cut to engage a bit. When cut engage is set, the feed complete output is cleared. As the shear continues to cycle, the feed initiate input is again set to start another feed.

Synchronous Profile Mode

In synchronous profile mode, the feeder is electronically line-shafted to the press. It follows an external reference signal, typically an encoder or resolver mounted on the press. By taking advantage of the full feed angle, this mode results in higher production rates while minimizing slippage. The feeder responds quickly to changes in line speed, allowing the line to accelerate rapidly without the risk of jamming. The feeder never operates faster than is necessary, thereby minimizing violence in the loop between the feeder and web delivery section.

Trapezoidal Mode

Trapezoidal feeding with S-curve smoothes the command by rounding the sharp corners of the velocity profile. While most feeders operate in a profiling mode, the trapezoidal mode can be used if a press-mounted encoder is not available.

Jog Feed

Jog feed is a manual function useful during set-up that jogs the feeder forward or reverses one part length. When the length is reached, the drive stops and remains in position. The drive can also be jogged any distance forward or reverse.

Single Feed

The single feed function feeds one length at a pre-programmed speed. The single feed input must be toggled for subsequent single feeds.

Micro Adjust

The micro-adjust feature minutely adjusts the feed length by adding or subtracting a programmable offset to the current feed-to-register length.

Quick Length Change

Lengths may be quickly changed on the fly by entering a new length into the next length location, then setting an input to make the changeover.

Multiple Part Counting

The operator can specify the number of parts to be counted in applications where multiple pieces are cut or stamped with each feed.

Batching

The operator can set up batches consisting of a number of feeds of a given length that the drive will feed before stopping.

Early Warning

An early warning output is set when the batch is nearly completed. The output can be used to alert the operator or to slow the line down and make other preparations.

Line Velocity Control

The drive calculates the maximum line velocity and outputs it as an analog reference signal for controlling the speed of the web delivery section. If a Unico drive is also used on the web delivery section, the reference velocity is communicated via a fiber-optic serial link for optimal synchronization.

Press Velocity Control

The press speed, in strokes per minute, is precalculated for each new job based upon the feed length, the engage angle of the die, and the limitations of the motor and drive.

Web Loop Control

The drive regulates the depth of the web loop between the press/feed and web delivery sections to prevent false web scoring, loop violence, and pulling tight. Loop depth is monitored using photosensors or a sonic device. The drive modulates the speed of the press and web delivery to maintain a requested depth. Different operating depths can be selected based upon flute size.

Press Cam Outputs

The program monitors the feedback device on the press, if one is mounted, and generates up to eight outputs that can be configured to turn on or off at specified press positions. These outputs can trigger various other line functions and replace mechanical cam switches.

Slippage Compensation

While most feeders operate using only a motor-mounted encoder to track material movement, the FTR™ drive has a feature that uses secondary feedback provided by a friction-driven roll on the web to compensate for the slippage. An input allows the user to selectively enable and disable this functionality.

Programmability

The control can be customized to a specific installation using UEdit™, a powerful Windows-based programming tool that lets users add their own ladder logic and function block programming.

Communication Protocols

The drive supports a variety of serial communication protocols for connecting to virtually any PLC or HMI. The drive can also operate in a stand-alone mode using the built-in keypad/display with an ANSI protocol connection to a simple serial display unit.

- CANopen

- CC-Link

- ControlNet

- DeviceNet

- Ethernet

- Interbus

- Modbus Plus

- Modbus RTU

- Profibus

- Remote I/O†

- RS-232/422/485

†Supported only by the 2000 family platform

Inputs/Outputs

All inputs and outputs are user-enabled and are mapped to hardware I/O points to allow customization of the control. They are also accessible through a high-speed serial communication link.

| Inputs | Outputs |

|---|---|

| motor on | motor on |

| fault reset | no fault |

| manual | manual |

| auto | motion |

| auto run | reverse motion |

| jog forward | forward motion |

| jog reverse | feed plus delay |

| jog feed forward | batch complete |

| jog feed reverse | line encoder enable |

| feed initiate | profile |

| motion enable | single-stroking profile |

| cut engage | pilot pin |

| line encoder enable | reject |

| single feed | feed complete |

| profile | press reference |

| single-stroking profile | feed error |

| load length | early warning |

| acceleration 1 | cam 1 |

| tuning 1 | cam 2 |

| fast stop | cam 3 |

| batch reset | cam 4 |

| reject | cam 5 |

| micro adjust reset | cam 6 |

| micro adjust positive | cam 7 |

| micro adjust negative | cam 8 |

| motor rms warning | |

| thermal warning |

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Contact Unico Support

- Unico

- 3725 Nicholson Rd.

- P. O. Box 0505

- Franksville, WI 53126-0505

- 262.886.5678

- Drop in your resume at –

- hr@wodehousecapital.com

- + 91 22 66336600

Talk to our Sales Team

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |