Testing of Electric and Plug-in Hybrid Electric vehicles has new challenges with respect to the ever-increasing demands of the EV market, the test cases, and the testing procedures.

Main questions arise from the fact that automotive companies have to balance testing coverage and risk with cost and time without compromising on the quality and effectiveness of the vehicle functions. Testing of such vehicles requires high testing standards to meet the required level of precision and the rapid advances in the EV market.

In order to get to the root of market-specific testing solutions, let’s identify the challenges and opportunities involved in the electric vehicle market.

Electric Car Market Growth

Automakers continued to invest in electric vehicle research and development, even during the COVID-19 pandemic, and the world has seen the strongest growth in EVs in the past two years.

The electric car market research shows that the industry which was valued at $162.34 billion in 2019, is projected to reach $802.81 billion by 2027, registering a CAGR of 22.6%. Factors such as the increase in demand for high-performance, cost-savings, fuel efficiency, and low-emissions are said to be the growth supplements of the electric vehicle market.

The accelerated global adoption of electric vehicles has led to an increase in demand for reliable and comprehensive testing solutions for better performance, safety, and overall satisfaction. Unico provides the exact solutions to help electric vehicle manufacturers get their cars and trucks faster into the market.

Unico’s solutions include in-depth knowledge of the R&D testing equipment for EV powertrains, including e-Motors, Traction Inverters, e-Axles, and battery packs.

Addressing the Challenges to Test Electric Cars

Unlike traditional vehicles, EVs are fundamentally different and present a new set of challenges and risks at testing.

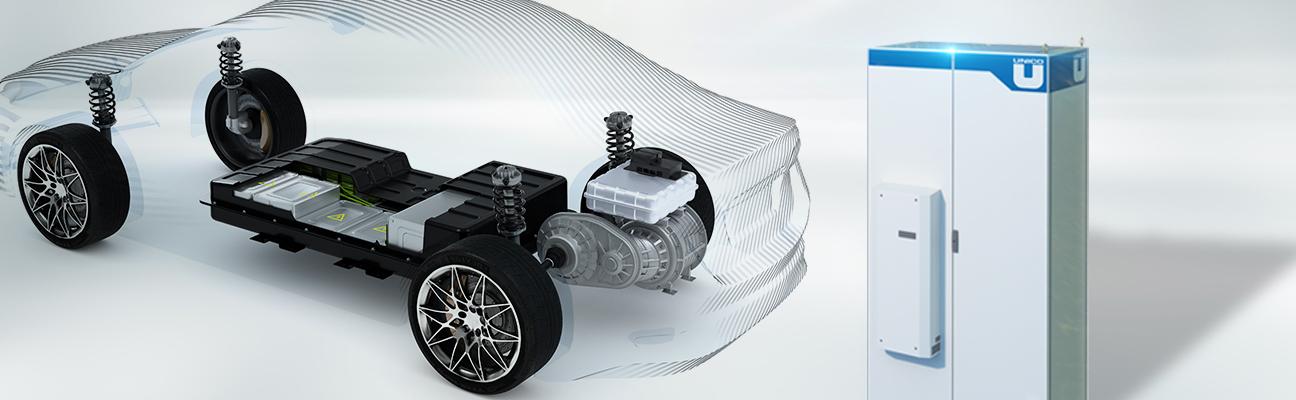

Powered by Lithium-ion batteries or other evolving EV battery chemistries, EV powertrains consists of three main powertrain components – a battery pack with a battery management system, one or more traction inverters, and one or more eMotors with gearboxes (sometimes also called an eAxle or eAxles).

The DC battery power is converted by a high switching frequency traction inverter into a sinusoidal PWM waveform to power the high-speed AC eMotor. The onboard charger replenishes batteries from the power grid, and a DC-to-DC converter steps down the power to lower voltage which is used to control the heater, power windows, and other vehicle accessories components.

All these powertrain components are rigorously tested under harsh conditions to ensure high reliability.

Other top challenges in EV testing include lithium-ion battery testing, battery simulation and emulation for inverter and eMotor testing, increasing the energy levels of battery packs for long-range, fast charging, improving efficiency, reliability, and complying with the government regulations in terms of emission control and monitoring.

Unico’s Flexible Approach to EV Testing

Unico has been quick to realize new challenges in testing all aspects of electric vehicle systems – from power packs to propulsion. We aim to meet these challenges in a very holistic and sustainable way.

In response to market requirements, Unico has developed flexible solutions for battery testing, including modules with standard ratings that can be connected together in series or parallel for increased voltage or current.

Battery simulation/Emulation is often supplied as a common DC bus design for integration into a system with other UNICO drives, thus providing a complete solution for Hybrid and EV drive train testing.

Additionally, Unico has incorporated performance characteristics within the drive systems to suit the new trend for smaller power units with fewer cylinders, higher power density, and peak torques.

Our superior approach provides a unique solution to create real-world conditions for testing complete powertrains under one roof.

Build and Expand the Existing Eco-system

Evolving customer needs and requirements are necessitating a shift away from traditional testing approaches. Customers are increasingly seeking test solutions that offer greater flexibility, convenience, fast response time, and more cost-effectiveness than ever before.

As a result, innovative business models that acknowledge specific customer pain points and barriers will be key to success in the EV market.

Unico has decades of automotive testing experience, with Unico systems installed in thousands of test cells around the world, holds a competitive edge in EV and Hybrid Vehicle Testing. With proven technology and a wealth of field experience, the engineers at Unico are constantly raising the bar to meet the demands of this dynamic market.

Considering how the automotive industry is evolving, the electric and hybrid electric vehicle market affords everyone in the industry a chance to adapt to new technologies and design and implement superior testing models.

Summary

The accelerated global adoption of Electric Vehicles coupled with rapid advances in electrification technologies has led to an increase in demand for comprehensive testing solutions in the automotive industry.

Unico provides testing solutions to enhance the existing product portfolio of manufacturers by meeting the challenges of the expanding market.

The key capabilities include:

- Engine Dynamometer Testing

- Hybrid Dynamometer Testing

- Transmission testing

- E-axle testing

- Battery Emulation/Simulation

- Battery Testing

- Torque Pulsations

- EV Component Testing

- FEAD Testing

- End of Line Testing

Get in touch with any of the Unico engineering experts, for all your testing needs. You will get a response within 24 hours.