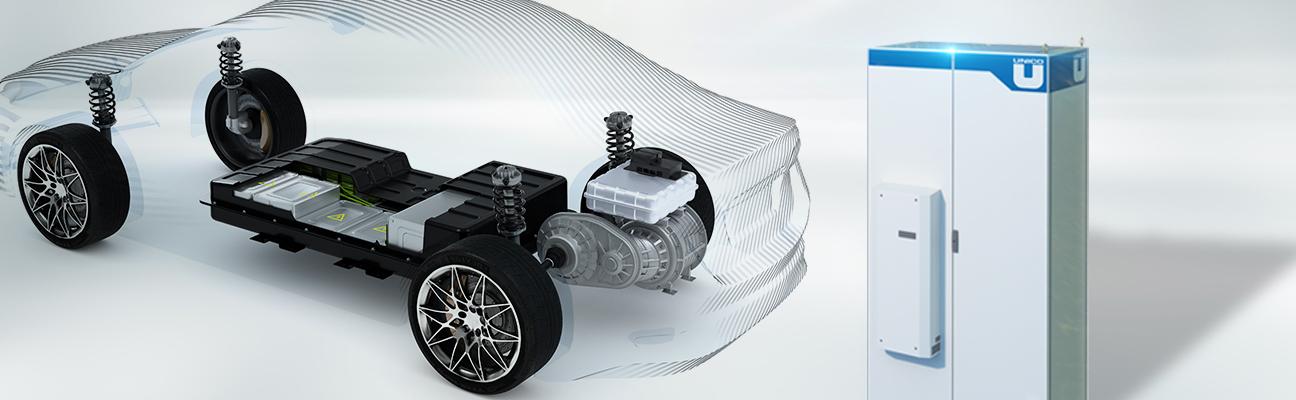

The E-Axle is becoming an integral part of the EV powertrain. It is an integrated E-Motor, transmission, and inverter package. Engineers responsible for E-Axle development that want more reliable testing, energy savings during testing, and a faster time to market, should consider the Unico E-Axle Dyno Drive System with a built-in Battery Emulator.

Engineering Efficiency

The brilliance behind this Unico drive system is the common DC bus architecture. Unico combines a battery emulator (that acts as the vehicle’s high voltage battery pack) and two AC dynos (that precisely absorb the spinning axle shafts of the E-Axle) in a single package that is powered by a single active front end.

This design saves floor space, reduces wiring complexity, simplifies installation, and saves energy. It is proven and reliable, highly efficient, and fully regenerative for immediate energy savings.

This is part of Unico’s new lineup of modular drive systems. Unico’s goal is to make it easier for testing engineers and systems integrators to build integrated testing systems – specifically designed for EV propulsion testing applications, while keeping install simple and systems highly efficient.

Unico E-Axle Drive Systems can handle a variety of power ratings from 50kW to 1000kW, with higher power rating systems available on request. The drive supports induction and permanent magnet motor dynamometers. The optional ripple generator (injects AC wave on top of DC output) is available for specialized testing. The common DC bus architecture allows for an add-on dynamometer controls sections.

Flexible Battery Cycling and Testing

For customers that are also developing high voltage EV battery packs in-house or need to perform extensive quality assurance testing on vendor sourced EV battery packs, Unico’s standalone battery cycler / battery tester is the perfect solution.

It is available in a variety of voltages, current and power ratings. Half bridge and full bridge technology is built-in, and allows for independent multi-channel configuration. Voltage and current ripple less than 0.1%. Insulation monitoring and remote voltage sensing options are available. Control modes include constant current, constant voltage, and constant power. Unico Battery Cyclers are installed in some of the largest battery test sites in the world.

Pushing it to the limit

Unico drive systems support most industry standard communication protocol, making it versatile to work with any available automation system platform. Multiple programmable and preset safety features are standard. Air cooled or water-cooled enclosures are available.

Unico E-Axle Drive Systems are installed at well-known automotive contract testing sites and within numerous OEM R&D labs for specialized EV propulsion testing. Additionally, the recognition of Unico drives for performance and endurance has resulted in the racing community using Unico drives to test high performance racing powertrains.

Unico’s engineering team, combined with world-class system integration partners, are the perfect team to help startup EV companies and automotive leaders achieve more accurate and reliable testing, to ultimately help them achieve a faster time to market.